Innovative Intelligent Inspection Solution

Enabled by the software Neith and based on Artificial Intelligence, 3iS ensures scalability and inspection repeatability on all production lines.

By deploying identical technology and software for each inspection phase, 3iS allows line engineers to have one single inspection program that can easily be shared not only among lines, but also among multiple manufacturing facilities through the cloud, allowing consistent results from multiple plants and a reduction of programming efforts. At the same time, the installation of Neith software on all the machines enables cross-training of operators, an extremely precise error detection and predictivity.

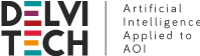

SMT Line

THT Line

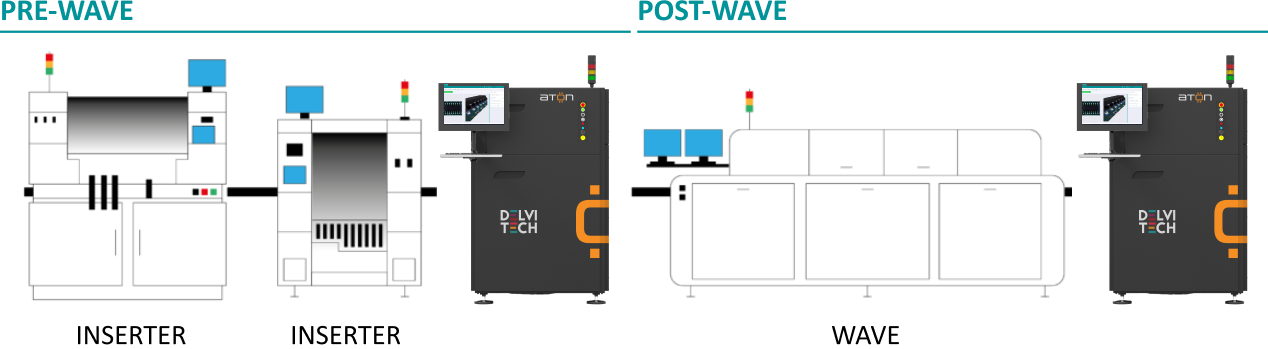

Optical Head Technology

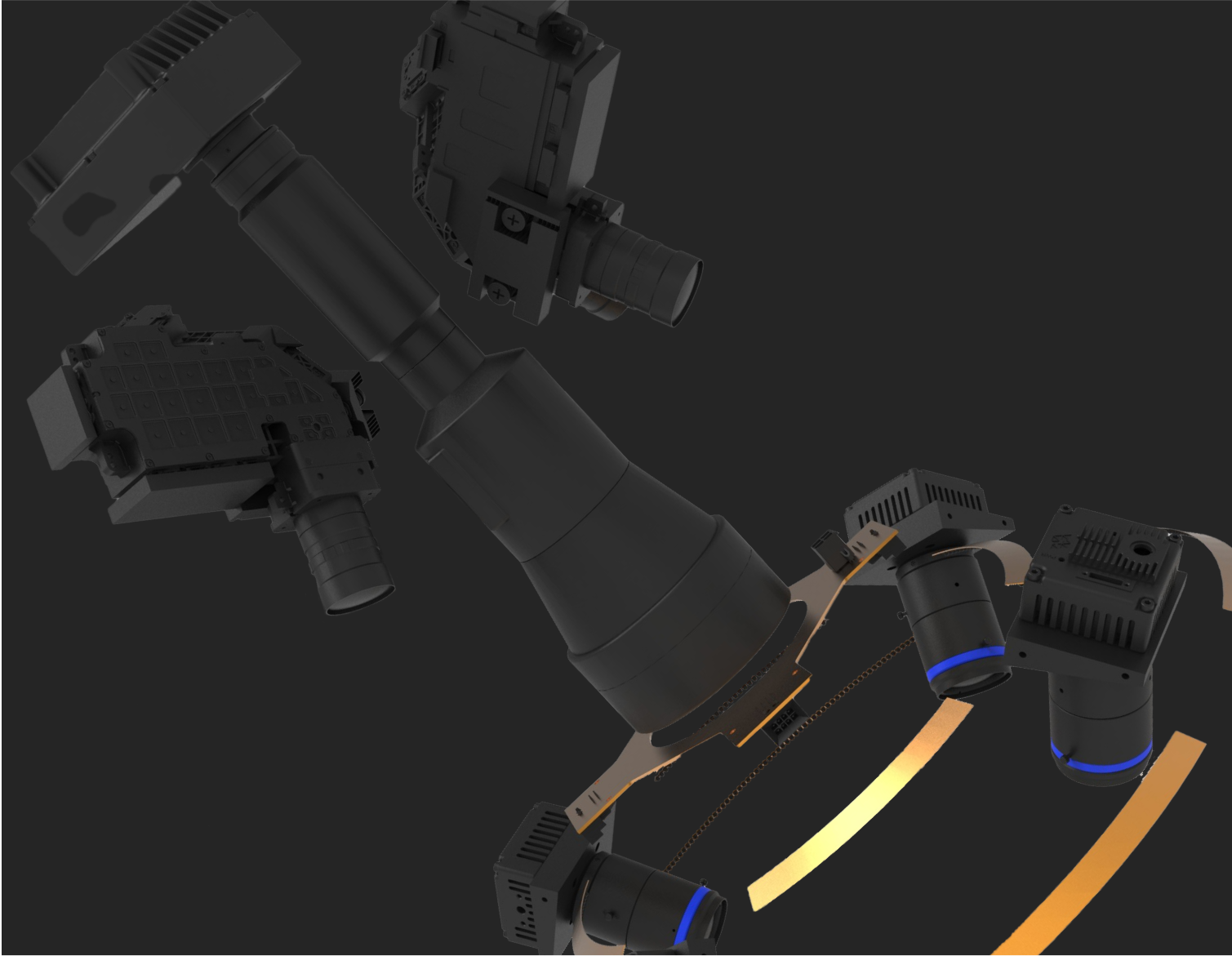

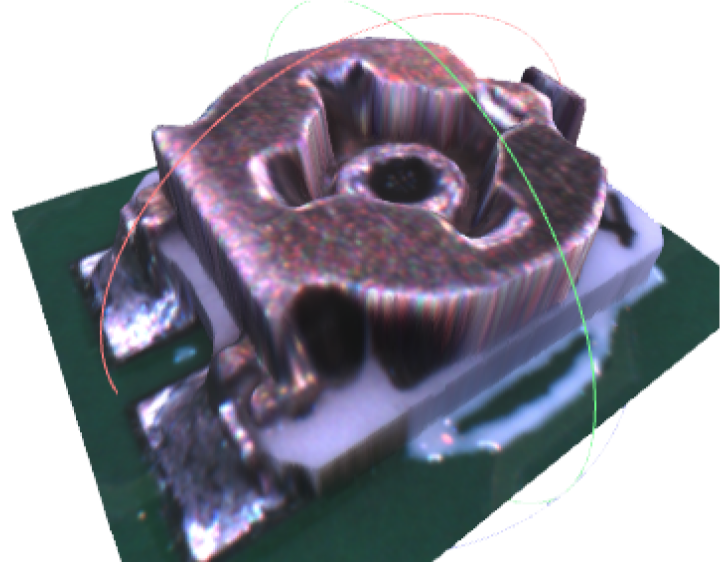

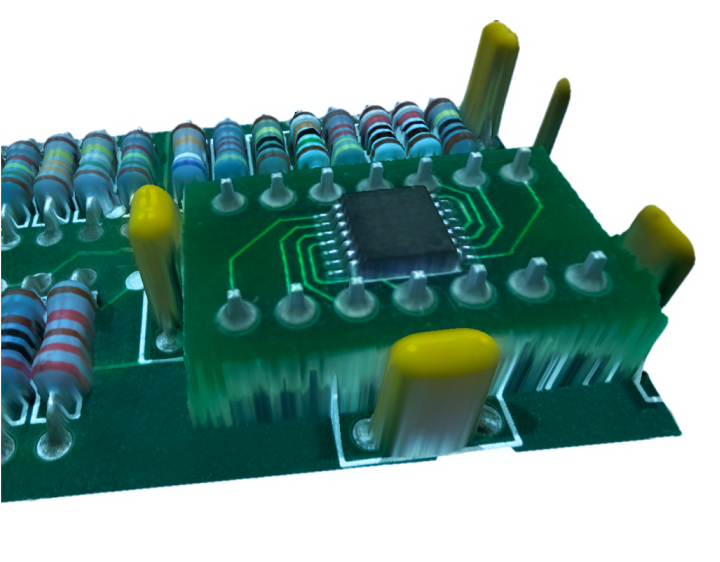

Real 3D Acquisition

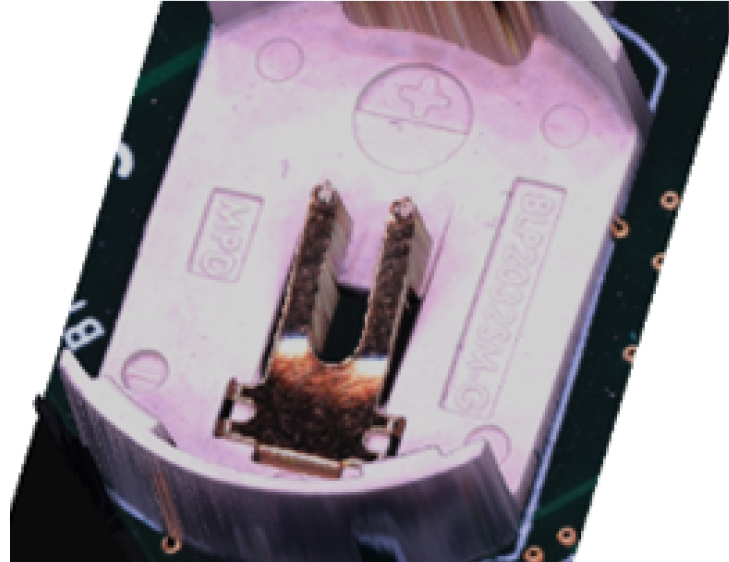

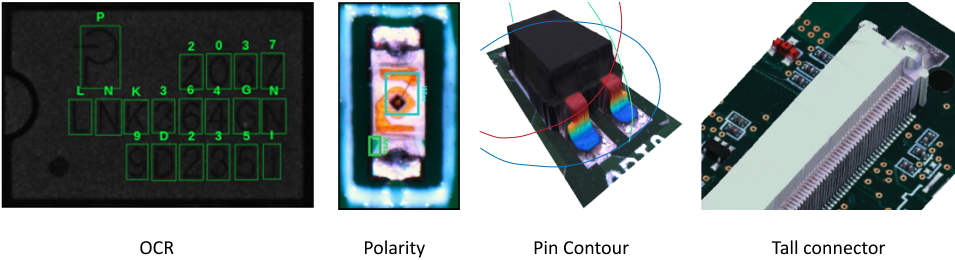

The patented optical head is a powerful technology that acquires precise 3D data with crystal clear images for a wide range of packages and components. From tall connectors with reflective metallic surfaces to fine pitch components, the 3IS technology provides a reliable and consistent performance to cover all scenarios in SMT and THT.

Created especially for Industry 4.0, Neith is a web-based software, compatible with multiple OS, that facilitates extensive data management by using AI, obtaining a higher production output, preventing defects and increasing the first pass yield.

Neith’s architecture is based on micro-services. The software features can be extended with customized services, such as personalized inspectors for specific components or ad-hoc interfaces based on existing protocols.

Advantages

- High customization

- Horizontal scaling

- Cloud scaling

- Shared package library

- Flexible computing power

- Rapid error fixing

Shared Package Library

Data, based on the client’s needs, can be stored locally within the company infrastructure, or on the cloud, allowing inspection programs, libraries and inspection results to be shared across multiple production plants and enhancing quality consistency.

Artificial Intelligence

Traditional parameter and threshold based AOIs face difficulties in adapting to all the possible variations during a production process. With Delvitech’s AI technology, complex variables can be computed with the help of sophisticated machine learning models.

AI and Inspection

Neural networks applied to inspectors are used to process images, minimizing the need for manual configuration and enabling unparalleled readability of components, especially under non-optimal conditions, thanks to the AI’s unmatchable ability to identify different variables and manage them.

AI and Training Manager

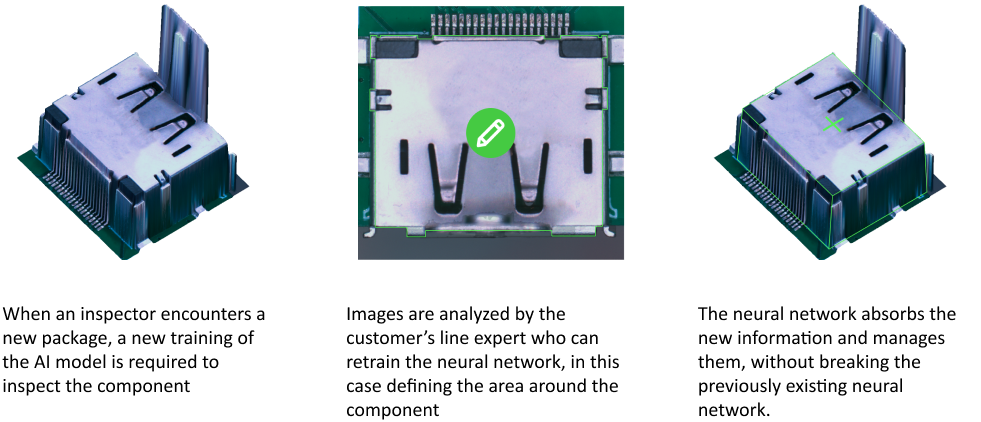

Delvitech’s solution is the only one working on a proprietary AI and that allows training to happen directly on the machine, activating a process of continuous inspection improvement, resulting in production efficiency.

Further Developments

Self-programming flows

Self-programming will operate in two different scenarios: during the assignment of inspectors, thanks to the ability to automatically recognize a component and assign it to the corresponding package within the package library, and during inspection, making automatic fine tunings directly during the production process to boost the first pass yield.

Predictivity

Delvitech’s AI will allow to detect errors even before they manifest, as it will be able to recognize process deviations within the sequence of boards produced, resulting in waste minimization, allowing the one of Delvitech to be the first 3D AOI sustainable solution.

Our Solutions

We offer 3D Artificial Intelligence-based Automatic Optical Inspection System for electronics industry

to enable the inspection and control of Printed Circuit Board (PCB) assembly processes.